Installations

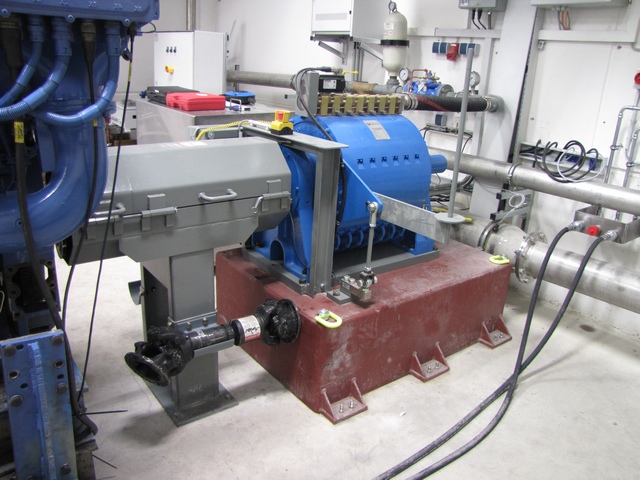

Power Test Europe installs a 1.000 HP (745 KW) engine dynamometer system at MB Services in Malta.

Tony Malia, CEO at MB Services :

Our dynamometer systems ensure perfectly reliable electric motor / gasoline or diesel engine testing and certification using water brake  technology. Water flow is applied at the inlet proportionally to the desired load, thereby offering resistance to the motor or engine. A simple acceleration and deceleration cycle creates a controlled, accurate load and the heated water is then discharged. In case of minimal loads applied for high speed, low torque testing, the inlet control minimizes the consumption of water in comparison to other styles of dynamometer.

technology. Water flow is applied at the inlet proportionally to the desired load, thereby offering resistance to the motor or engine. A simple acceleration and deceleration cycle creates a controlled, accurate load and the heated water is then discharged. In case of minimal loads applied for high speed, low torque testing, the inlet control minimizes the consumption of water in comparison to other styles of dynamometer.

During operation, power ranges from 20 – 1000 HP and speeds reach up to 6000rpm. A special alloy construction reduces inertia.

The dynamometers are equipped with a universal cart that can hold up to 6000 lbs running weight and allows for a flexible, efficient method of mounting the engine in the proper position. After connection, jacket water temperatures can be kept by using the engine cooling column (on liquid-cooled engines). Thermostatic control protects effectively against overheating.

The system’s monitoring & control package is easily connected to any computer and produces results in readable file formats. Diagnostics, test results and standard engine tests are stored on hard disk and any previously run test can be loaded and re-run. Full automation of engine throttle and load control (via an electro pneumatic water valve) ensure repeat accuracy. Alternatively, manual entering of setpoints by the operator is possible.

Motherwell Bridge Ltd.

Hal Far Industrial Estate

Hal Far BBG 3000

Malta

Europe

Tel: +356 2165 7800

Fax: +356 2165 7801

Power Test Europe installs a 2.350 KW dynamometer system at Viertel Motoren, Germany.

At Viertel Motoren in Nuernberg, Power Test Europe has delivered and installed a 45X07 (2.350 KW / 3.150 HP) dynamometer system to test their engines. Max torque they can test is 15.220 Nm.

Viertel Motoren with more than 100 employees is one of the leading engine overhaul companies in Germany with experience in the field of diesel engines, transmissions and axles since more than 40 years.

Christian Viertel : We choose for a Power Test dynamometer system due to their simplicity of the dynamometer and a reasonable price. Also the data acquisition with the PowerNet software is easy to operate, very advanced and operator friendly. Besides this, the support we received during the installation of our dynamometer system was very professional. We are very happy with the system and have much confidence in the future.

Furthermore we are able to test a big range of engines from 125 KW up to 2.350 KW with only one dynamometer. Due to their unique Servo Load Control Valve system they are able to make very quick load changes and they are also able to close a number of sections of their dynamometer so you can easily use only 5% of the max capacity of the dynamometer system.

Viertel Motoren GmbH

Sigmundsstrasse 154

D-90431 Nuernberg

Germany

# # #

Power Test Europe

The Netherlands

22-4-2013

“TrackMaster at MABO Engineering”.

Stuska Europe has just recently installed a “turn-key” 1600 HP Trackmaster system at MABO Engineering in Dedemsvaart, The Netherlands. This new company in Dedemsvaart, with Maurice Boessenkool at the steering wheel, has just finished their well designed brand new testcell and is now fully equipment for tuning their performance engines.

The Trackmaster system is equiped with 12 thermocouples 0-900 Celsius, 2 pressure sensors for oil pressure and boost pressure, 2 low temperature sensors 0-150 Celsius and a fuel flow sensor. The system has an integrated weather station to correct measured performance values to SAE or DIN standards. All measured values are presented in SAE or Metric units.

With their fast responding Innovate LC1 lambda sensor, they are able to map their engine in a professional way. After setting the complete fuel map they are able to make “Sweep” tests to see the HP output of their engines. Also static testing with their new 1600 HP Trackmaster system with waterbrake is one of the possibilities. They can continuously hold the engine at any stable speed as they have a big reservoir with water outside the testcell.

Maurice Boessenkool, managing director at MABO Engineering : “We are very pleased with the new 1600 HP performance engine dynamometer of Stuska. The installation of the new system went very well and we are very pleased with the support Stuska has provided. Right from the start we were able to make performance runs without any problem”.

MABO Engineering can also be contacted for tuning your engines. All engines, up to 1600 HP can be tuned. For contact details, see below. For e-mail contact, This email address is being protected from spambots. You need JavaScript enabled to view it..

Stuska Europe

Jos Swagemakers

Halsteren, The Netherlands

Tel +31 656 05 17 95

MABO Engineering

E-mail : This email address is being protected from spambots. You need JavaScript enabled to view it.

Office : +31 (0) 523 61 44 19

Mobile : +31 (0) 624 28 76 66

Power Test Europe installs 35X05 engine dynamometer at Voith Turbo in Crailsheim, Germany

At Voith Turbo GmbH & Co. KG in Crailsheim, Germany, Power Test Europe has delivered and installed a 35X05 engine dynamometer to test the Voith Turbo prototype gearboxes. This 1750 HP ( 1305 KW) dynamometer, with 8500 Nm of torque, is to load several gearboxes in-line with a 1000 KW electric motor.

Voith : "We are very surprised about the noise of the dynamometer. We can almost not measure any noise. Also the stability of the system is very good. We test with a continuous load of 1000 KW without any problem at the waterbrake system".

Power Test Europe

Halsteren

The Netherlands

Voith Turbo GmbH & Co. KG

Voithstrasse 1

Crailsheim

Germany

Dutch Engine Distributor MTU Benelux Installs First Dynamometer from Power Test Europe

U.S. Engine Testing Equipment Maker Sets New Focus on European Market

For this important inaugural installation of equipment from Power Test Europe, company CEOAlan Petelinsek and technical specialist John Miller came from the US to commission the installation and train the customer on this system. “The technicians and engineers at MTU Benelux as well as their German colleagues from MTU Friedrichshafen were very pleased and impressed with the results of the first tests,” says Petelinsek. “They especially enjoy the stability of the system and also its ability to test a wide range of engines on a single dynamometer system. These factors, they said, together with the user-friendly operating software, are a huge improvement over the previous system they had been working with.”

Power Test Europe